Bid for a new land in Shandi Industrial Zone, Danxi Town

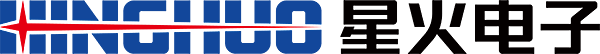

Development of connector for automotive radar

Awarded the title of Wenzhou City’s First Batch of Industry-Education Integration Sites

Innovative small and medium-sized enterprises in Zhejiang Province

Development of energy storage connector and door handle actuator

Completion and acceptance of the new plant in Shandi Industrial Zone of Danxi Town and put it into use

Passed SA8000:2014 social responsibility management system certification

Passed QC080000:2017 Hazardous Substance Process Management System Certification

Awarded the title of Green Factory in Yueqing City

Acceptance of three digital workshop demonstration projects in Zhejiang Province, Wenzhou City, and Yueqing City

Passed the IATF16949:2009 Quality Management System Certification

Passed the ISO14001/45001 Management System Certification

Embarked on the path of international trade, with products exported to Europe, North

Developed motor connectors and door handle antennas

Established school-enterprise cooperation with the Department of Information and Electronic Engineering of Zhejiang University

Awarded the title of "Yueqing City Enterprise Technology Center"

Honored with the titles of "National High-Tech Enterprise"

Awarded the title of "Wenzhou City Enterprise Technology Center"

Passed the ISO9001:2000 quality management system certification

Relocated to the Second Industrial Zone of Danxi Town, Yueqing City

The second phase of the factory was expanded

Build a 100000 level dust-free workshop and put it into use

Yueqing Xinghuo Automotive Electronics Co., Ltd. was established

40+

Monthly production of molds(set)

2000+

Existing stamping mold quantity(set)

1200+

Existing injection mold quantity(set)

0.002

Minimum precision of mold processing(mm)

3

WEDM-LS West Slow Silk Road(unit)

10

EDM Mitsubishi Electric Pulse(unit)

13+

High speed punch press

35+

Horizontal Injection Molding Machine

45+

Vertical Injection Molding Machine

8+

Industrial robot

50+

Automatic assembly machine

IATF16949

QMS

ISO14001

EMS

ISO45001

OHSMS

SA8000

CSRMS

QC080000

HSPM